Exploring the Intricate Process of Custom Cast Plaques

Custom cast plaques offer many options for size, shape, fill color, background texture, border style, and mounting method. They are ideal for professional offices, universities, government buildings, and commemorative purposes.

When casting a high relief, it is essential to ensure that the molten bronze alloy can reach every part of the form before cooling. Otherwise, the surface may appear worn down over time.

Materials

Cast metal plaques are highly durable and designed to withstand the elements, unlike stone and wood plaques, which can break down over time. They are a long-lasting alternative for commemorative plaques, trail markers, and memorials.

Clearly define your requirements for the plaques you need and select a supplier that offers suitable options to match your envisioned aesthetic, budget, and intended use. Look for a supplier to accommodate special requests, such as adding a metal photo or etching line art into the plaque.

Flat reliefs are a less expensive way to add photos to plaques but only sometimes capture the person’s likeness.

Design

Custom plaques, including border, background color, and texture, can be sculpted to your specifications. Typically, backgrounds are leatherette or pebble textures to contrast with the raised metal elements.

You can select a standard finish, a darker bronze, or other specialty finish such as oxidized or dark oxidized finishes, Verde patina or turquoise patina, or duranodic bronze. A clear coat is usually added to protect the painted background and polished metal surface.

For a more contemporary look, consider adding a raised logo or emblem. This can be done using a tooled plaque process, which offers the same enduring distinction as cast plaques but looks more modern and up-to-date.

Tooling

Plaques are long-lasting and offer a timeless aesthetic appropriate for public and private spaces. Choosing metalworking projects Los Banos CA, supplier with experience and a reputation for quality craftsmanship is essential to ensure the plaque you receive meets your preferences and installation needs.

The tooling process involves creating the plaque design and a mold from it. Molten bronze is poured into the mold, forming the plaque’s pattern.

The raised lettering and graphics on cast plaques stick out more than those on etched plaques, making them easier to read from a distance. Almost any letter style can be reproduced on a cast plaque.

Casting

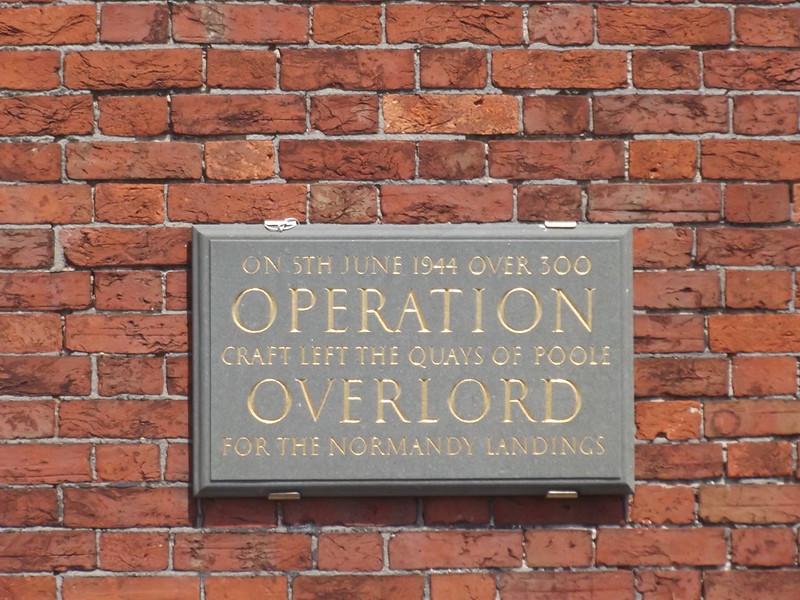

Cast plaques add a sense of timelessness and prestige, perfect for commemorating achievements and significant historic events. They can be displayed in professional offices, universities, government buildings, and public spaces.

A cast bronze plaque requires liquid, molten metal to be poured into a sand mold and cooled. They have raised letters and graphics, a raised border, and a recessed background. They are also available with standard single-line borders, double-line borders, or beveled-edge border techniques.

Precision-tooled plaques are an excellent alternative for those on a tight budget. They are computer cut from vectorized art files and can be brushed, painted, light or dark oxidized, polished, or patina finished.

Finishing

Incorporate images or logos, border styles and texture, mounting options, and coloring techniques to create a unique plaque that tells your story.

Cast and precision tooled bronze and aluminum plaques are great for professional offices, universities, government buildings, and commemorative events. They are available in various depths and have extensive finishing options, including brushed, oxidized, patina, and paint.

Installation

Whether you’re looking to honor someone, celebrate an event, commemorate a historic site, or recognize a company milestone, metal plaques are a long-lasting and timeless solution. Select a supplier with experience with your project’s size and complexity to achieve your vision.

Bronze and aluminum plaques are created in a foundry by pouring liquid, molten metal into a mold. They feature raised dimensional lettering and graphics and a recessed background texture.

Chemical etching can transfer even the most finely detailed line art and photos to brass, bronze, or stainless steel. Etched photos have a newspaper-style dot pattern, and the text is painted in contrasting colors for readability.